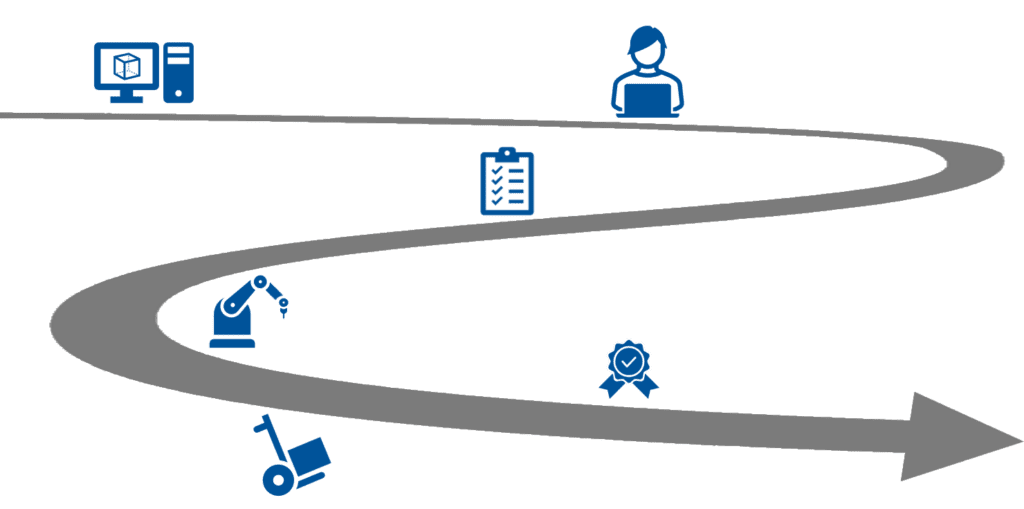

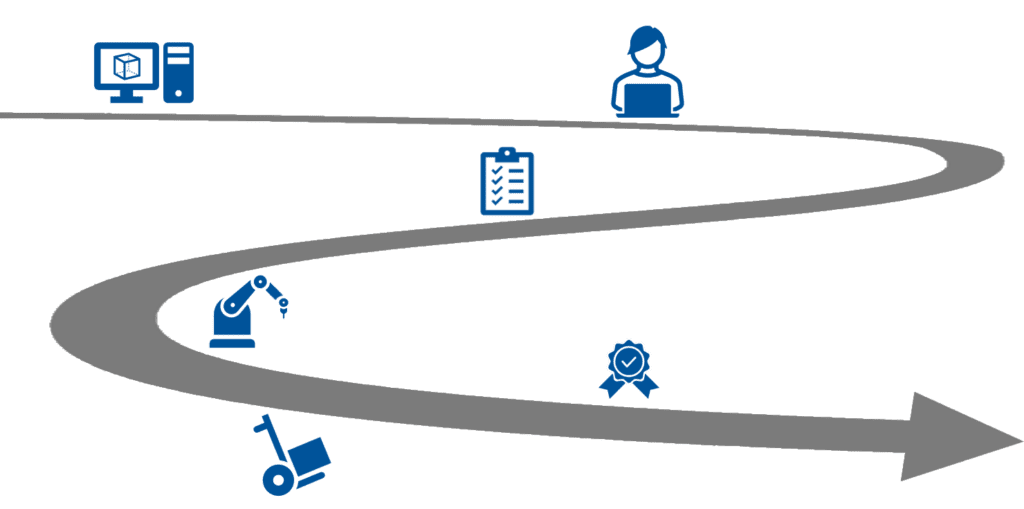

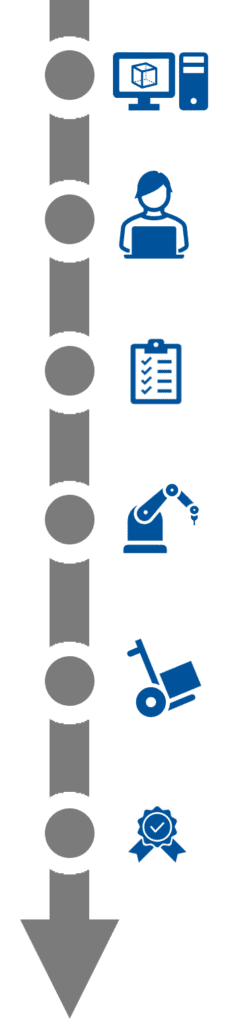

CAM systems are excellent at generating toolpaths. But before you ever post code, someone has to decide how the job will run: which tools to use, how to structure the operations, and how to communicate that plan to the shop floor.

MachiningCloud gives that part of the process a home of its own.

Create jobs with part, material, machine and due-date info

Define and sequence operations for each job

Assign tools and assemblies to every op

Capture feeds & speeds and cutting conditions alongside the job

Many shops manage tools with a combination of spreadsheets, CAM libraries and people’s memories. That works—until you try to scale, standardize, or onboard new programmers.

MachiningCloud replaces scattered lists with a structured, shareable tool inventory.

Build a centralized tool and holder library

Create multi-brand assemblies with accurate 3D models

Tag tools by material, operation, machine or customer

See which tools are used on which jobs and machines

Good machining decisions start with good data. MachiningCloud combines manufacturer information with your job context to help you choose the right tools and parameters faster and with more confidence.

Use machining recommendations based on material and operation

Apply manufacturer-based feeds & speeds as a starting point

Capture proven parameters from your own jobs as you gain experience

Reduce trial-and-error on the machine

You already own a library of tools. The problem is turning that into usable digital data. MachiningCloud’s user upload and AI capabilities help you turn tool lists into a live inventory with much less manual work.

Upload tool lists and have MachiningCloud help build the digital twins

Use brand and part numbers to fetch available information

Reduce the effort of populating TMS and CAM libraries

Move toward natural-language search for tools and jobs

The value of any job planning or tool management system depends on the quality of the data it holds. MachiningCloud works directly with cutting-tool manufacturers to provide accurate, up-to-date information in standard formats.

Manufacturer-verified data for tools, holders and assemblies

ISO-compatible information and STEP/STL/GTC models where available

Consistent representations across brands and product lines

Digital twins ready for CAM, simulation and TMS

Empower your team to collaborate and preserve institutional knowledge. Share files, documents, and insights effortlessly, ensuring everyone stays informed and aligned.

Real-time editing and commenting capabilities facilitate efficient teamwork, even across different sites. Moreover, MachiningCloud maintains a comprehensive history of all jobs, enabling future employees to access and learn from past projects, decisions, and best practices.

By fostering a culture of knowledge sharing and collaboration, MachiningCloud drives innovation and empowers your team to achieve greater success.

You now have access to seamless online orders through an exclusive partnership with MSC Industrial Supply Co.

Prepare your carts directly in MachiningCloud ,and complete your purchases on MSCdirect.com using your account and discounts.

You now have access to seamless online orders through an exclusive partnership with MSC Industrial Supply Co.

Prepare your carts directly in MachiningCloud ,and complete your purchases on MSCdirect.com using your account and discounts.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.